Slump Test for Concrete

Slump test for Concrete used to determine the workability of concrete at construction site.| Degree of Workability | Slump | Suitable to Use |

Very Low | 0-25 | Used in Road work |

Low | 25-50 | Used in Foundation with light reinforcement road vibrate by hand operated machine |

Medium | 50-100 | Used in normal reinforced concrete manually compacted and heavily reinforced section with vibrations. |

High | 100-175 | Used in section with congested reinforcement. Not normally suitable for compaction. |

Advantages of Concrete Slump Test:

1.Slump test is very easy and simple. Even non-technical person can perform it in construction site without any problem.

2.This test does not require any special or costly equipment and not to send the sample at laboratory. It can be done in the construction area.

3.It is very essential to check batch to batch or hour to hour variation in the materials which will be fed into the mixer. Too high or too low slump is an indicator of unwanted workability of concrete and mixer operator gets an alarm to find a solution to remedy the problem.

4.Slump test does not demand a long-time period to get the result. We can obtain slump value within some minutes.

Limitations or Disadvantages of Concrete Slump Test:

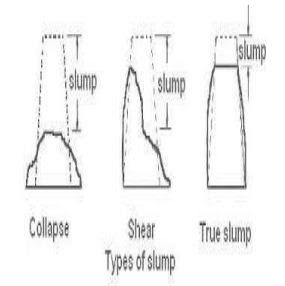

1.It is unreliable for lean mixes. In a lean mix, a true slump may convert into shear or collapse easily. Widely variation can be found from one sample of lean mix and it can be a great confusion to determine the exact result.

2.It cannot differentiate in workability of stiff mixes as it shows zero slumps. In dry range, no difference can be detected between different mixes with different workability.

3.It is not exact measurement because slump bears no unique relation to workability. Even, for different types of aggregates, the same slump can be recorded for different workability.

4.For a specimen, more than one shape can be resulted confusing the correct result. If shear slump occurs, it may attain true slump in next test.

5.It is not suitable for concrete formed of aggregate higher than 40 mm.

No comments:

Post a Comment