Aggregate Impact Value | Classification |

| <20% | Exceptionally strong |

| 10-20% | Strong |

| 20-30% | Satisfactory for road surfacing |

| >35% | Weak for road surfacing |

Together we will try to Recall our Civil Engineering knowledge here..................

Determination of Aggregate Impact Value

Importance Of Fineness Test of Cement:

The property of cement that indicates particle size of cement and specific surface area is called fineness of cement. Rate of hydration greatly depend on fineness of cement and a for a rapid development of strength, high fineness is required.Here we can list the importance of cement fineness test:

1) It affect hydration rate of cement and it turns into strength. Increasing fineness increase the rate of hydration, high strength and high heat generation.

2) Bleeding can be reduced by increasing fineness.However increasing fineness demands more water for workability resulting a higher possibility of dry shrinkage.

3) The smaller the particle size the greater the surface area to volume ratio, thus the more area available for water -cement interaction per unit volume.

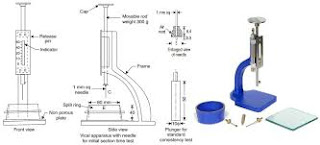

Importance of soundness test of cement

4) It also used to check the proper grinding of cement and measure the surface area of the cement particles per unit mass.

|

| Cement fineness test |

Cement Test

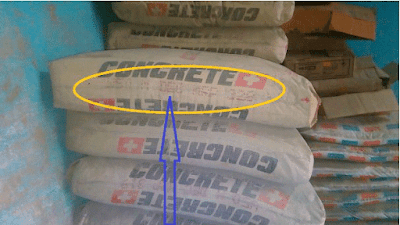

Field Test of Cement

Field Test of Cement

Field Test of Cement: Cement is the most important ingradient for construction work. It plays vital role because it is the binding material. So ensuring good cement in construction work is important to know the field test of cement . |

| Cement Test |

|

| Cement Test |

|

| Cement Test |

Water Absorption test of Bricks

নির্মাণ কাজের উপযোগী ভালো বালু চেনার উপায়

ভালো সিমেন্ট চেনার উপায়

Test on Bricks

CBR Test (সিবিআর টেস্ট)

ভালো ইট চেনার উপায়

Loss Angeles Abration Test (এল এ টেষ্ট)

| গ্রেড | বল সংখ্যা | বলের ভর |

| A | ১২ | ৫০০০(+/-)২৫ |

| B | ১১ | ৪৫৮৪(+/-)২৫ |

| C | ০৮ | ৩৩৩০(+/-)২৫ |

| D | ০৬ | ২৫০০(+/-)২৫ |

| E | ১২ | ৫০০০(+/-)২৫ |

| F | ১২ | ৫০০০(+/-)২৫ |

| G | ১২ | ৫০০০(+/-)২৫ |

-

Field Test of Cement Field Test of Cement: Cement is the most important ingradient for construction work. It plays vital role because it i...

-

Clear cover of Concrete As per ACI Code Clear Cover: Clear cover can be defined as the clear distance between the surface of the concrete an...

-

Types of Building Foundations Foundations are basically of two (02) types. Types of Building Foundation are as follows: 1) Shallow Found...

-

Bearing Capacity of soil from SPT Value Bearing Capacity of Soil: Bearing Capacity is the capacity of soil to support the loads applied ...

-

Lapping in Reinforcement L apping in Reinforcement: Lapping length of reinforcement is one of the important term in RCC. It is a very confu...

-

Types of Shallow Foundation Shallow Foundation: According to Terzaghi, if the depth of foundation is less than or equal to its width, then ...

-

Slump Test for Concrete Slump test for Concrete used to determine the workability of concrete at construction site. Apparatus: 1) Slump Cone...

-

Best Concrete Paint: Concrete Paint: Concrete paint is a durable and versatile solution designed to protect and enhance concrete surfaces. I...

Lapping in Reinforcement

Lapping in Reinforcement L apping in Reinforcement: Lapping length of reinforcement is one of the important term in RCC. It is a very confu...